Lunar Landscape

These amazing bubbles were sighted in our fermenter. We are so inexperienced that we do not know if we should be proud of them or frightened.

These amazing bubbles were sighted in our fermenter. We are so inexperienced that we do not know if we should be proud of them or frightened.

When he retrieved it from the basement, it was dirty and had oil stains. Perfect. Chuck gave it a quick rinse with the hose, and I was assigned the task of applying a clear, thick, hard bar coat to the top of it. The first two applications met all of these requirements. The third did not dry properly. It remained sticky and soft in large areas. It took months to get it ready for a fourth application.

With each application, there were drips down the sides of the bar top. I was going to remove them when the project was finished, but began to enjoy the sight of them growing. With each additional application, the drips began to resemble stalactites.

We have had many visitors to the distillery as we prepare to open. I have been surprised at how many compliments I have received on my stalactites. Children especially like them.

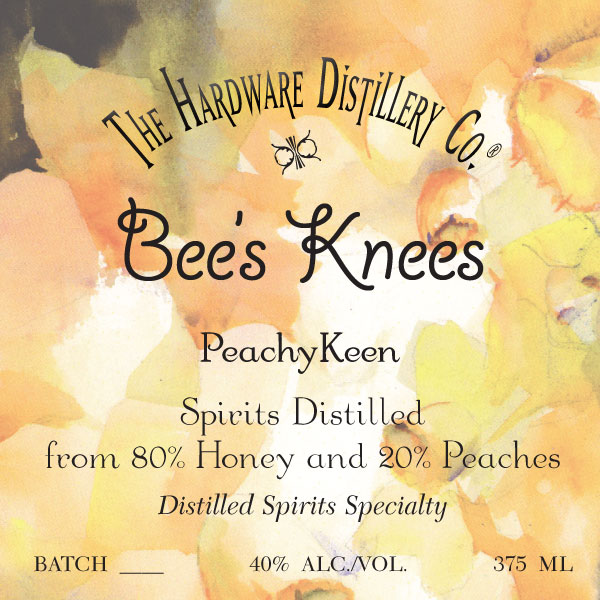

It is in a category of its own, and is considered a “specialty” by our government (the Tax and Trade Bureau, or the TTB), as it does not fall into the usual TTB categories, such as brandy.

As usual, things have been both easier and more difficult than expected for our Bee’s Knees®.

Making our Bee’s Knees® has been easier than expected in that every batch has been successful, but the fermentation time of the honey has taken three times longer than expected. So, we have far less of it than we had thought we would.

The labels have not been easy. We started the label process in December, and still do not have our labels. Our formula has been approved, and as we wait for a decision on our latest attempt at meeting all of the font and style requirements, we are hopeful that we have seen the last rejection from the TTB.

We have made Bee’s Knees® from raspberries, peaches, plums, and pie cherries. Some of the batches of peaches and plums are aging in new American oak barrels, and should be ready by mid-summer. In the meantime, un-aged Bee’s Knees® will be available as samples in our tasting room over the Memorial Day weekend, but we cannot sell bottles until we have approval of our labels. And all of that comes down to the right font in the right place. Something I had never imagined would be so difficult.

We’ve been working toward this day for a long time, and finally it’s here! Our tasting room opens on Friday, May 24.

We will be open Friday, Saturday, Sunday, and Monday (Memorial Day), May 24-27, noon to 6 p.m.

Thereafter, our regular hours will be noon to 6 p.m. on Fridays, Saturdays, and Sundays.

Hunter Farms is a local farm near our distillery.

They sell fresh eggs, delicious ice cream, and have fall and winter events for families.

Last weekend they collected our spent grain to feed their chickens and other livestock. As I write this, I am pretty certain that those happy chickens are dining on single malt barley.

Hunter Farms eggs are beautiful, and the whites of those eggs will be used in our whiskey sours.

To make wort, one must first grind the grain, and then cook it in a mash-tun. After that, it goes to the fermenter, until it is ready to be distilled.

These first steps are the brewer’s job. On the surface, this sounds simple enough, but, trust me, it is not easy, and brew masters are expected to make a much better beer than a distiller.

So far, in my few weeks of experience, I would say that brewing is more difficult than distilling. Time may change my view. These are some of our experiences with beer so far.

We bought a good grist mill to grind our grain. Unfortunately, we wired it incorrectly and the rollers were going the wrong direction. Instead of grinding the grain, the grist mill was flinging the grain all over the distillery.

When we got the grist mill rollers moving in the right direction, we initially ground the grain too fine, and the grain plugged up the mash tun, plus we had misunderstood how to put the mash tun together. As a result, the process of moving the wort from the mash tun to the fermenter became a very slow process. It took 8 hours, instead of 45 minutes.

In addition to the slow moving wort, we had some problems with the chiller, which the wort was supposed to pass through on its journey from the mash tun to the fermenter, which was now a very slow journey. Something happened, and cold water flooded the distillery. Our plan to use the chiller was abandoned for this first batch. This turned out to be okay, as the wort was moving so slowly that it had plenty of time to cool itself, plus it gave us plenty of time to clean up the flying grain. It is a miracle that we had any wort on our first attempt, but we prevailed. It was, sadly, a small amount of wort, and it was very late when we finished.

Yeast and babies enjoy the same things. Mostly, they like to be warm, cozy and well-fed.

This past weekend I continued work on our peach honey mead. The mixture of warmed peaches and honey told me when they were ready for the yeast. It just looked right: warm and comforting with lots of sugar. I knew the yeast would be happy, ready to begin its new life. It reminded me of the days when my children were babies.

Last week we started our first fermentation.

Last week we started our first fermentation.

We bought honey from a beekeeper in Snohomish County and made a peach honey mead from last summer’s late harvest peaches. We pitched the first yeast early in the day and a second yeast in the afternoon. By nightfall it was smelling fragrant.

When we left the distillery we were greeted by the moon.

January has been a very good month for us.

The Mason County Building Department gave us our certificate of occupancy, the Department of Labor and Industries gave us our final electrical, and we passed the Liquor Control Board inspection today.

WE ARE NOW DISTILLERS. Our sign is up and we are ready to begin!

We will be open by appointment beginning in March, and we hope to have regular hours beginning in late May.

Last week Chuck met the Mason County building inspector at the distillery for the final inspection. The work we have done was approved, but there is one new item: emergency back-up light in the basement, where we will be storing our barrels. Chuck immediately drove to Olympia, bought the light, and returned to the distillery in the emerging blizzard of heavy wet snow. The lights went out, and he installed the emergency back-up light in the dark basement.

We have been having a very wet winter at the distillery, and the ground is thoroughly wet. That day trees loudly broke in half under the weight of the heavy snow. Many were uprooted. Fallen trees littered the road. Chuck finished installing the light and began his drive home. It was now dark, and it took him hours to drive around the trees, and travel a few miles.

This photo was taken a week after the storm. Due to the snowstorm and the holidays, the inspectors are behind with the inspecting. Our next inspection is scheduled for January 2, and we are hoping our back-up light passes inspection and that we will finally have our certificate of occupancy.

With all of the work we have had to do for the Mason County Building Department, we have not had a chance, until a week ago, to begin assembling our second still.

This still is from Artisan Still Design in Canada. It will be used for our gins, and many other spirits.

We are so excited to start distilling, and hope to meet all of the requirements of the building department before Christmas.

The Mason County building department is slowly adding to its list of requirements for the Certificate of Occupancy for the distillery.

The front of the Distillery has two double doors. These doors were custom made, and we like them very much. One of the double doors opens into the production area. We have no employees, and Chuck and Jan will be distilling in the production area. Usually, it will be just Chuck, while Jan works in the tasting room.

Originally, when we started the project, we had thought the big expense for the doors would be the locks required by the federal TTB. Early in the project we had these locks installed. But that was the least of the door requirements. First, the Mason County building department had us put an exit sign above the doors. This sign had to meet certain requirements. Then, they wanted the locking system changed, and the dead bolt moved from the door on one side to the door on the other side. (Chuck will be safe from the stampeding people.) Then there was the required fire alarm system, and components for that system were added on one side of the doors. The first week of December was the week for several new fire extinguishers, and one has been installed next to these doors.

The doors are beginning to look garish with all of the accoutrements. But wait, that’s not all. Now we have been informed that the exit sign is not sufficient. We must buy back-up lighting to put above the doors to help Chuck find his way out.